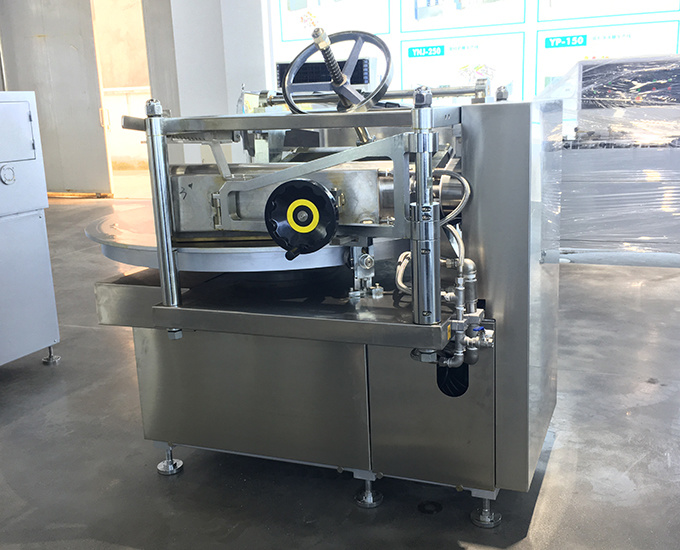

Common faults of single twist chocolate packing machine

2021-09-15

1. The knife seat is too high or too low, the packaging speed is too fast, and when the push rod and the cutter are not synchronized, the single twist chocolate packing machine cutter will cut on the product. The maintenance method is to reduce the packaging speed and adjust the height of the end sealing parts. Make the center of the sealing knife in the middle of the product height.

2. The color of the film color mark is too light, the film drive slips, and the cutting position deviates from the color mark when the color mark tracking is not turned on. At this time, the maintenance method is to refer to the packaging machine manual and adjust its sensitivity; in the man-machine dialogue interface, Switch the Tracking Mode to "Track Cut".

3. If the temperature is too high, the speed is too slow, and the heat resistance of the outer layer of the coating is poor, there will be scorched and wrinkled marks on the seal. The maintenance method is to increase the speed, lower the temperature, and replace the film material.

4. The single twist chocolate packing machine solid-state breaker is burnt out, the temperature control meter is damaged, and the thermometer cannot control the temperature when the thermocouple is damaged. The maintenance method is to replace the thermocouple, the temperature control meter, and the heating element.

Ready to Go Wealth Machinery

Learn why we're different and how you beneft!

With a 40-year history of the brand, our products have been exported to Southeast Asia, the Middle East, the European Union, and the Americas, where they enjoy a high reputation.

Contact Information

info@rgfoodsmachine.com

info@rgfoodsmachine.com

0086-15162740800

0086-15162740800

Whatsapp:008615162740800

Whatsapp:008615162740800

No. 201, Qingyu East Road, Rugao City, Jiangsu Province

No. 201, Qingyu East Road, Rugao City, Jiangsu Province

Copyright © 2022 Nantong Wealth Machinery Technical Co.,Ltd. 苏ICP备17059472号 Powered by:www.300.cn SEO